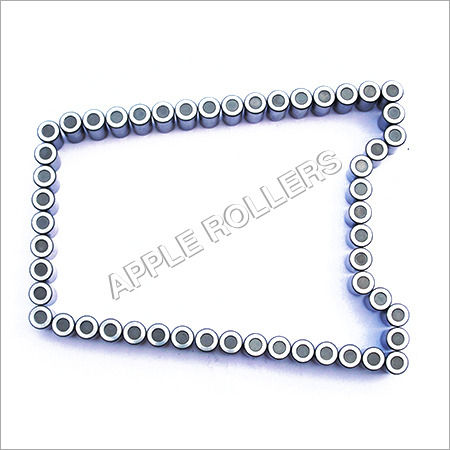

Loose Taper Roller

Product Details:

- Material SAE 52100

- Roller Bearing Type Taper

- Click to View more

X

Loose Taper Roller Price And Quantity

- 50000 Piece

Loose Taper Roller Product Specifications

- SAE 52100

- Taper

Loose Taper Roller Trade Information

- MUNDRA

- Telegraphic Transfer (T/T) Cash in Advance (CID)

- 45 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- AS PER CUSTOMER REQUIREMENT

- South America Western Europe Africa Central America Eastern Europe Middle East Asia North America Australia

- All India

Product Description

Accredited by IATF 16949 : 2016 certification, we are betrothed to manufacture, export and supply our clients a broad array of Loose Taper Roller. The provided roller is ideal for accommodating larger axial forces when used as bearing in different kinds of conveyor systems and machinery. This roller is manufactured at our in-house production unit using topnotch quality metal alloys and avant-garde techniques in adherence with international quality standards. Sternly tested on defined quality parameters to assure its smooth surface, this Loose Taper Roller can be purchased from us in different lengths, finishes and diameters at competitive prices.

Features:

- Durable finish standard

- Easy installation

- Corrosion resistance

- High strength

-

TOLERANCE CHART FOR SUPER FINISH TAPER ROLLERS

6 mm to 20 mm

SR. NO.

PARAMETERS

REFERENCE

CLASS - I

CLASS - II

1

Ovality

2 Point

1 m

2 m

2

Roundness

15 : 500

0.6 m

1 m

1 : 500

1 m

1.6 m

3

Dia variation per Lot

-5 to +5 m

-7 to +7 m

4

Dia Grouping in each Bag

3 m

5 m

5

Surface Roughness

on OD

0.10 m

0.15 m

6

Surface Crowning

on OD

As per Requirement

As per Requirement

7

Length

00 to -250 m

00 to -300 m

8

Taper

on OD

-3 to +3 m

-4 to +4 m

9

Hardness (HRC)

on Face

62 + 2

62 + 2

10

Surface Roughness

on Face

0.20 m

0.25 m

11

Face Runout

10 m

12 m

12

Face Radius

+ 15 mm

+ 15 mm

13

Material

SAE 52100 / 100Cr6

SAE 52100 / 100Cr6

Advantages Of Apple :

| Minimize Friction | Maximize Life of Bearings |

| Minimize Heat Generation | Maximize Load Bearings Capacity |

| Minimize Energy Consumption | Maximize Geometry of Bearings |

| Minimize Running Noise Assembly | Maximize Efficiency of Bearings |

Details:

- Big diameter - 6 mm to 24 mm

- Length - 9 mm to 42 mm

- Angle - 1o 29' to 8o 30'

INTERNATIONAL EQUIVALENT MATERIALS

| USA | ITALY | FRANCE | GERMANY | SPAIN | JAPAN | CHINA |

| SAE 52100 | UNI 100CR6 | ANFOR100CR6 | W.NR.1.3505 | UNE F1310 | SUJ 2 | GCR 15 |

Taper Rollers Main Applications:

- Automotive

- Industrial

- Hydraulic

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Tapered Rollers' category

We are dealing only in Bearing Rollers